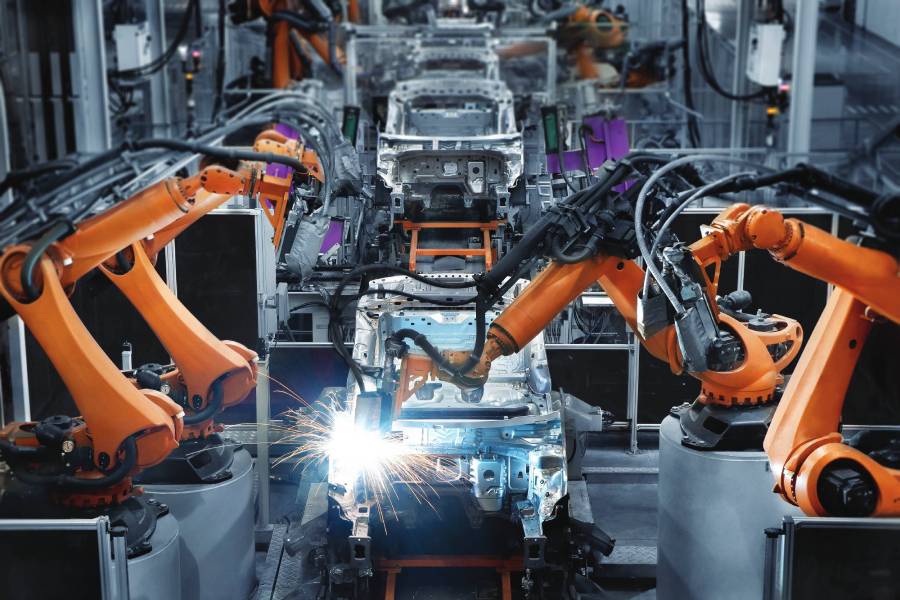

The pace of digital transformation in industrial real estate has been considered as not so rapid compared to other sectors because the industry is physically based on construction and land bank expansion. It is much easier to adopt digital innovations for a tech company than it is for an industrial zone developer who still runs on hard copy and spreadsheet, except that DEEP C is not that kind of “old-school” real estate player.

Technologies are changing the way it does business with customers, tenants, partners, and employees at a giant pace, especially the way it positions itself. Rather than providing industrial space and utilities for factories to nestle, DEEP C aims to make an impact by creating a smart industrial zone with the help of technology where tenants can thrive in a sustainable manner.

The first step of the mission is monitoring energy supply and distribution via a low-power wide-area network (LPWAN) technology and Internet of Things (IoT) smart meter reading technology, which was never achieved before in Vietnam.

DEEP C employees analyses energy consumption data

CHALLENGE

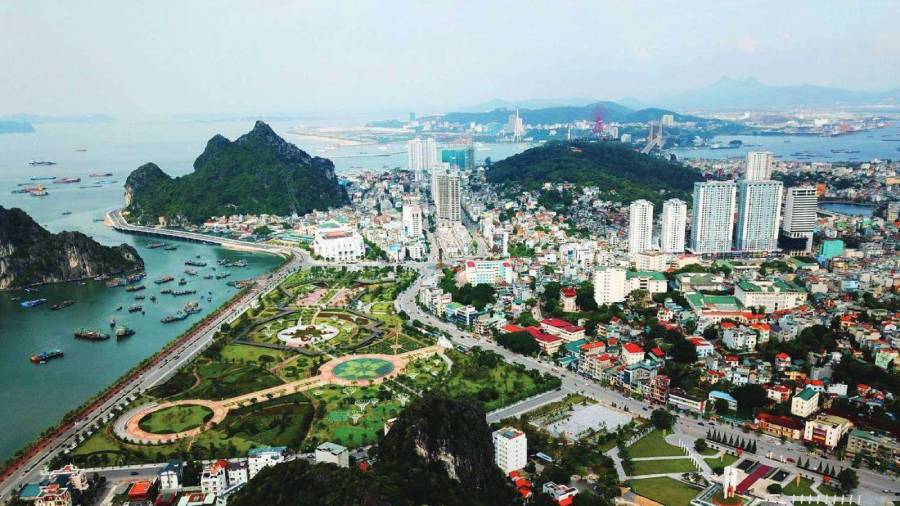

DEEP C Industrial Zones operates in a vast size of 3,400 ha of industrial land, divided into three industrial zones in Haiphong city and two in Quang Ninh province. In addition, the group provides a large portfolio of services to ensure its zones up and running: land reclamation, road construction, development of energy and water supply infrastructures, port operations, marketing, security, facility services, wastewater treatment, etc.

The scale of the area and the diversity of services are major reasons DEEP C started looking for a solution to automate the collection and analysis of the energy and environmental data of the infrastructure it operates.

"A large part of our activities, which are particularly diverse, were still carried out manually. They were demanding in terms of human resources." explains Niels Hubert, COO of DEEP C Green Energy, one of the group's entities.

He added: "Since we were operating in a large area, we needed an automation solution to collect information to better organize our own activities. We looked into several types of technologies and ended up opting for LoRaWAN (Low-Power, Wide Area Network) technology. Its advantage is to allow the remote collection of large amounts of data and low-cost information transfers in areas where availability of power supply sources and communication network coverage are not optimal. We also needed a solution to process this data in the most practical way possible. This is how we started working with Opinum, a company that, just like us, focuses on energy services and environmental impact."

SOLUTION

DEEP C already rolled out the first project, deploying sensors in roughly 100 factories in DEEP C Haiphong I, one of the group’s industrial zone in Hai Phong and automatically collecting power consumption information of each factory.

"Our first need was to better understand how our electrical distribution services work. We need to collect more data regarding our customers’ consumption, currently about 100 of them, and the necessary capacities. We already had installed smart meters for all our clients, we only had to set up a communication network and software to extract and process the data.

It is at this stage that we turned to Actility and its ThingsPark Enterprise solution to ensure a stable and secure communication over the LoRaWAN network from the sensors to the servers and Opinum for data analysis and insights. DEEP C therefore partnered with a local system integrator, namely the Vietnamese subsidiary of the Japanese operator KDDI.

It should be noted that the deployment of a remote energy data collection solution, via LoRaWAN connections, was a first in Vietnam.

Niels Hubert - COO of DEEP C Green Energy working on the system

RESULTS

Power consumption data are now collected every 30 minutes. Whatever the activities of industrial customers, data is collected and centralized in a fixed set of variables: voltage, capacity, consumption. This serves two purposes: on one hand, precise and transparent data collection of customer’s consumption profile and, on the other hand, more efficient management of the DEEP C energy grid. And all of those are executed at a lower cost and less energy consumption than the traditional manual method.

"The data, now available in real-time and in large quantities, will allow us to better plan our maintenance interventions," explains Niels Hubert. "In the past, interventions had to be made in a preventive or reactive manner. In 2020, we will be able to implement predictive maintenance programs, based on trends, and anticipate actions to be taken.”

The first project, involving the deployment of around 100 sensors, will validate the efficiency, accuracy, and reliability of the solution. Based on the results and lessons learned, a roll-out to all five zones managed by DEEP C will take place within a few months. The number of sensors will then increase gradually to several thousands.

In addition, some customers have already expressed an interest in being able to access certain consumption data. "First we want to check that the solution is stable and works perfectly. But in the future, it could clearly become an additional service that we would offer to our customers, to meet their specific needs" said Niels.

FUTURE PERSPECTIVE

DEEP C services are constantly evolving, so is the technology integration into all aspects of its business. A diversification of energy supply sources is underway, via the deployment in 2020 of renewable energy generation from wind turbines and solar panels on the rooftops of factories. The group also intends to expand the technology to its water distribution and wastewater treatment activities handled by DEEP C Blue entity, and other facility management activities managed by DEEP C Park Operations.

For DEEP C, digital transformation is more than implementing the technology, it’s about how the company defines itself: the next-generation industrial zone, that is to say, an industrial zone that drives sustainable growth and meets future needs of customers/tenants through the medium of technology.